Provision of potable water in Hong Kong is a highly challenging task. Faced with a population of 7.51 million residing in a tiny area of 1,107 km2, we have had to develop ingenious solutions and extraordinary expertise in the management of water supply in Hong Kong.

Fresh Water Supply System

Hong Kong enjoys one of the safest and most reliable water supplies in the world. The fresh water supply system has been extended to cover not only the populated city centres and satellite towns but also rural areas and villages covering a total of 99.99% of the entire population. With the ever-improving living standards of society, the demand for quality water supplies increases as well.

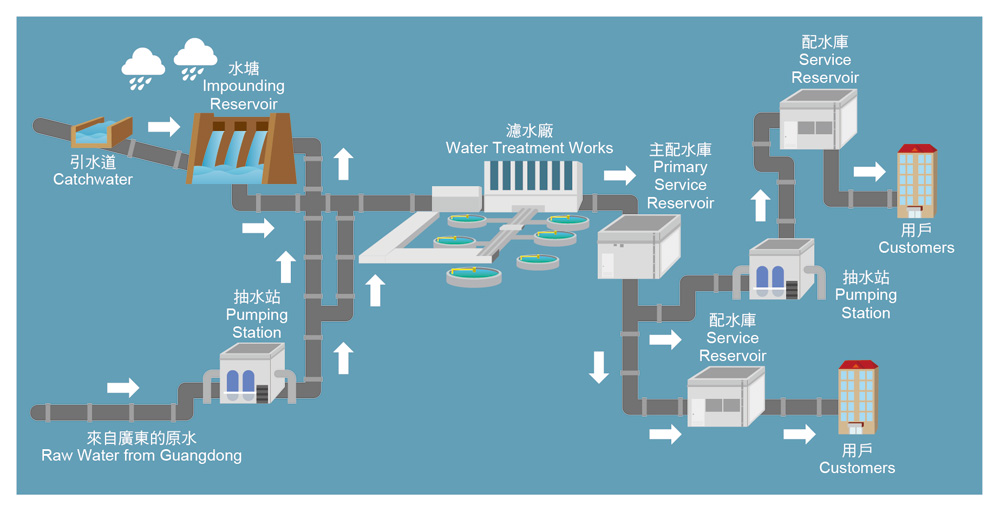

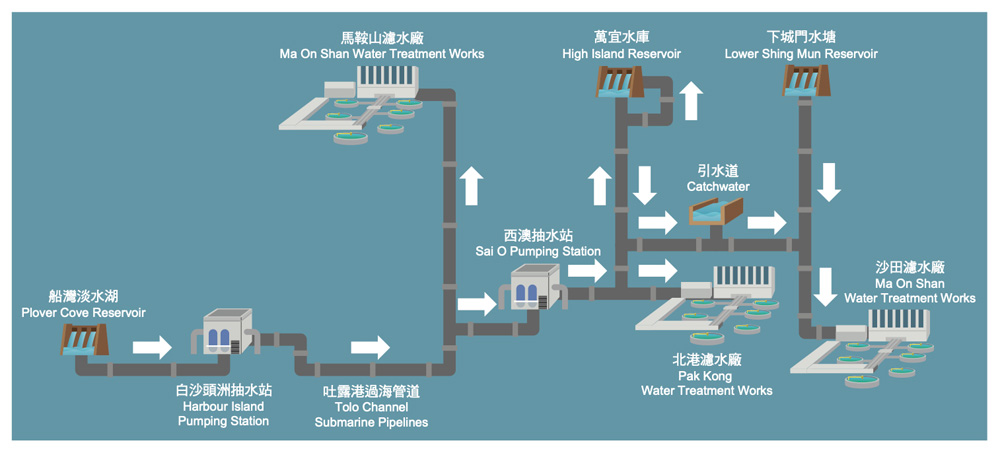

Fresh water supply mainly involves three key processes, viz collection of raw water, water treatment and distribution. Thousands of kilometres of underground pipes including several submarine pipes across Victoria Harbour carry the water in a complex web-like network all around Hong Kong. Raw water from the impounding reservoirs and Dongjiang is delivered by large transfer mains and tunnels to water treatment works for treatment. Treated water is then pumped through large trunk mains or tunnels to service reservoirs and then flows by gravity via the distribution network to the various buildings – residential, commercial, hotels and restaurants, factories and warehouses, etc. – and arrives at the destination of its delivery journey – the tap.

Rain that falls onto the local water gathering grounds (also known as local yield) but is not absorbed into the ground is collected and channelled through a network of 120 km of catchwaters – concrete channels conveying the collected flow to impounding reservoirs.

Catchwaters and supporting installations such as tunnels and aqueducts were constructed to transfer the collected rainwater (also known as local yield) to the reservoirs. Here the collected rainwater and any surplus raw water received daily from Dongjiang is held until it is required for the next stage in the supply process.

Raw water pumping stations deliver water from impounding reservoirs to water treatment works for treatment while fresh water pumping stations take treated water from water treatment works to service reservoirs for transient storage and distribution.

Each pumping station basically houses pumps and control equipment. Pumping stations can be manned or unmanned. They can be operated either in automatic mode or remotely from a regional control centre. To maximise energy efficiency and cost-effectiveness of construction, pumping stations are mostly located close to either reservoirs or water treatment works.

Huge effort has been made over the years to ensure sufficient treatment capacities of fresh water for Hong Kong. There are now 20 water treatment works with a total capacity of 4.68 million m3 per day. Being a universal solvent, water contains all kinds of dissolved substances. The treatment process is not intended to remove all impurities in water. Instead it purifies the raw water to drinking water standards. In Hong Kong, the quality of treated water fully complies with the Hong Kong Drinking Water Standards.

The roof of a service reservoir is covered with turf for greening purpose

There are now 178 fresh water service reservoirs with a total storage capacity of 4.35 million m3 located in different locations across Hong Kong. They provide transient storage for fresh water to cope with peak demand and help manage the supply water pressure. They also provide a buffer for maintaining supply when the trunk mains are not operating (e.g. during maintenance).

Service reservoirs are normally constructed on high ground so that gravity will help provide enough pressure to supply water to the customers through the distribution network. Service reservoirs are generally built of reinforced concrete wholly or partly under the ground and are designed to blend in with the surrounding environment. Trees and bushes planted around the perimeter of the reservoirs insulate the structure to moderate temperature fluctuations. The roofs of reservoirs are covered with turf or hyroseeded as a greening measure. Some reservoir roofs have been converted to playgrounds open for public use.

Distribution mains are the pipes transporting water from service reservoirs by gravity to the taps of our homes in every part of Hong Kong. More than 8, 000 km of raw water and fresh water mains have been laid over the years. They stretch above ground and underground; cross the harbour in submarine pipelines and feed urban and rural areas alike. The pressure in the water distribution system is generally sufficient to convey water to buildings several storeys high above street level. The pipes are large enough to make sure all customers can get sufficient water at peak consumption hours. They are also designed to provide enough water for the fire brigade to put out fires when needed. Usually these pipes range from 20 mm to 2,400 mm in diameter.

Service pipes branching from distribution mains deliver water into houses and buildings. A water meter is installed at the supply pipe leading to each unit or apartment to measure the amount of water used by each household. If you are a domestic customer, a meter reader reads your meter every four months and the first 12 m3 of water consumed over a four-month period is free of charge. Water Supplies Department (WSD) bills customers for the amount of water used during the period beyond the free supply volume and the charges are based on a tiered system with rising unit cost. For further details about water bills, please visit Price of Water – Water Tariff Structure in Hong Kong.

For water supply to the upper floors of multi-storey buildings or apartments of modern skyscrapers, fresh water from the service pipes first enters the underground tanks of the buildings and is then pumped through the internal pumping systems to the roof tanks. From there, water is distributed down to the flats or apartments on different floors. The internal plumbing systems in buildings are not part of the public water infrastructure, and are under the care of the building owners or property management companies. The internal plumbing systems must be kept in good and clean condition, or else they can be a potential weak link of the water supply chain.

To ensure tap water quality, a voluntary Fresh Water Plumbing Quality Maintenance Recognition Scheme was launched in 2002 to promote the proper maintenance of plumbing systems in buildings. The scheme was re-titled "Quality Water Recognition Scheme for Buildings", "Quality Water Supply Scheme for Buildings – Fresh Water" and "Quality Water Supply Scheme for Buildings – Fresh Water (Plus)" (Q-Plus) in January 2008, March 2015 and December 2015 respectively to signify enhancement features.

Flushing Water Supply System

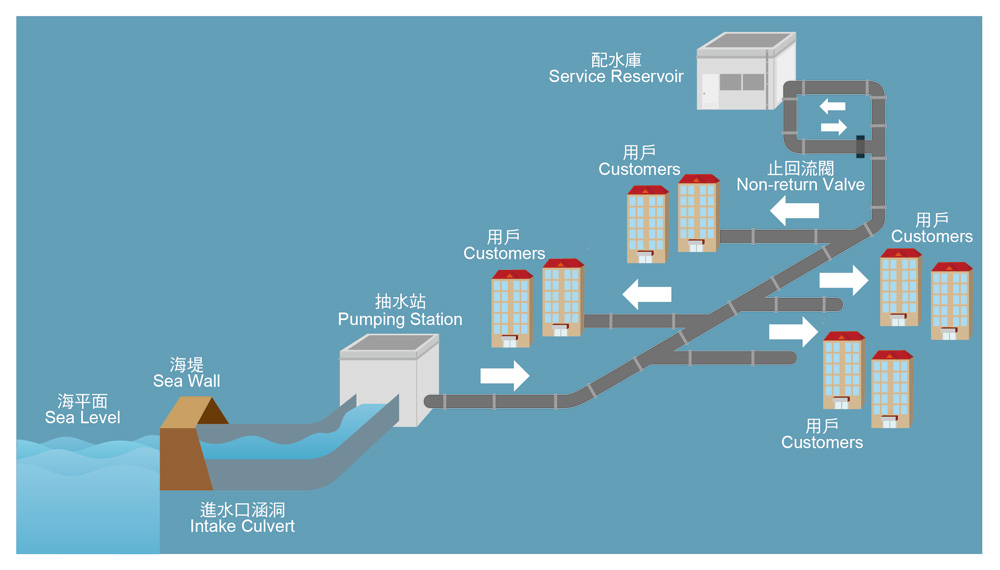

The flushing water system is completely separated from the potable water supply system. The system normally uses a "balance tank" configuration. Seawater is directly pumped to the customers with surplus water delivered to and stored at the service reservoirs. The whole flushing water system consists of 35 pumping stations, 54 service reservoirs with a total storage capacity of nearly 0.26 million m3 and 1,800 km of water mains. Water main materials are mainly cement-lined ductile iron, cement or epoxy-lined mild steel and plastic (polyethylene).

Most of the salt water pumping stations are located on or near sea fronts enabling direct pumping of seawater into the flushing water distribution network. Screens are installed at intake structures to keep debris from entering the pumping stations. The pumps are mostly made of stainless steel and installed at a level below sea level in a typical deep pump hall. Sodium hypochloride is generated on site by electrochlorination plant and dosed in the seawater for disinfection before the seawater is supplied to the customers for flushing. The residual chlorine will also help prevent marine growth in the distribution pipes.

Seawater for flushing is supplied free of charge.

Differences between fresh water and seawater supply systems

- The fresh water system starts with the catchwaters across Hong Kong's hills and country parks; the seawater system begins with the intake structure and the screen at the sea front where water is piped in from the sea.

- Raw water pumping stations are normally located close to the impounding reservoirs; seawater pumping stations are always located close to the sea intake that brings the water ashore.

- Fresh water and seawater have completely separate storage and supply systems.

- The end products are for different uses: fresh water for human consumption, industrial and commercial business, etc.; seawater for toilet flushing

Similarities between fresh water and seawater supply systems

- Both types of water require the addition of chlorine for disinfection.

- Both systems are divided into different supply zones with pumping stations responsible for the supply to specified areas.

Water Supplies Department (WSD) is mindful of the essential role of water supplies in the sustainable development of Hong Kong. A Triple Bottom Line (TBL) concept is therefore applied to all decisions in the provision of water supplies to ensure that an optimal balance of the economic, social and environmental aspects for the community can be reached.

Water Infrastructure Management

Management of the water infrastructure is crucial for the provision of a sustainable water supply. Creation of new infrastructure such as building pumping stations and a supply network is only part of the story. The crux is to maintain the existing infrastructure assets to sustain system reliability and viability into the future. To this end, a holistic approach to managing the water infrastructure components covering a whole spectrum of surface and underground assets such as reservoirs, treatment works and water mains has been adopted by WSD.

Asset management in the context of water supply is about applying the best management practice to the entire portfolio of assets seeking to minimise the total life cycle cost in the delivery of a desired level of service within an acceptable level of risk. The life cycle of an asset consists of planning, acquisition, operation, maintenance, replacement and disposal. Asset management and risk management frameworks have been put in place to provide a springboard for continuous improvement of the asset performance. Condition assessment of the infrastructure asset is under way to facilitate the formulation of the maintenance and replacement plan. Central asset and risk registers have been compiled to enable better understanding of the asset portfolio and the risks associated with management of these assets. An overall asset management plan is being developed to document our policies, strategies and practices for managing the creation, operation, maintenance and rehabilitation or replacement of the supply systems. This ensures a desired level of service as highlighted in the Performance Pledge, which covers quality of water, pressure and flow, reliability of water supply and standards of customer service.

Long Term Planning

The planning and creation of water infrastructure facilities to match the water demand of the territory's population requires a good understanding of Hong Kong's growth patterns and projections.

Demand projections are made and updated on a regular basis by WSD, working closely with the territory's planners. The development of new water supply facilities – whether for pumping, treatment, storage or distribution – is generally based on demographics. These facilities will have to fit in with any new town developments, or new housing and commercial needs. Three key planning factors include: land availability, economic considerations and environmental friendliness. In selecting the locations of these installations, long term growth should also be taken into consideration.

In light of environmental protection, instead of building new facilities, existing facilities can in many cases be upgraded to meet the demands of changing demographics. Refurbishment projects are undertaken carefully, appropriately applying energy sources where possible and making use of new technology to improve efficiency.

Efficient Operations

A Supervisory Control and Data Acquisition (SCADA) system has been widely used by WSD for remote monitoring and control of the operations of the reservoirs and pumping stations. Operations are split into four distinct regions – Kowloon, New Territories East, New Territories West, and Hong Kong & Islands. Each region has its own Regional Control Centre to oversee the operations of the water transfer and distribution facilities in the region. With the assistance of the SCADA system and surveillance equipment, the safety, security and efficient operations of the facilities is maintained round the clock.

The advancements in technologies in recent years have enabled an increase in the level of automation of the waterworks installations. State-of-the-art Distributed Control System (DCS) is deployed in each water treatment works. Sophisticated computerised panels and multi-screen LCD monitors replace conventional push-button type control panels to allow streams of information to be displayed concurrently. This enables automating the treatment process and keeping manning level to a minimum.

CCTV coverage at water treatment facilities enables operators to maintain a close surveillance of the plant and machinery. Real time plant operating parameters are sent to internal users to enable efficient decision-making and appropriate levels of forward planning.

Effective Maintenance

For the mechanical and electrical machinery used across the water supply systems, a risk-based maintenance strategy has been developed to enhance the reliability of pumping stations and treatment works. Under this strategy, great emphasis is placed on the understanding of failure risk and on-condition monitoring of equipment. Appropriate maintenance actions commensurate with the asset conditions, asset criticality and potential of failure are taken when necessary.

Sustainable Operations

WSD was awarded the ISO 50001 Energy Management System certification in December 2014

As one of the largest energy consumers in Hong Kong, WSD has implemented measures to reduce its carbon footprint as much as possible through the development of renewable energy and enhancing energy efficiency.

WSD set up the Energy Management Committee in 1998 to formalize and rationalize our existing energy management strategies and practices to improve our energy efficiency and save energy cost.

To achieve a higher standard in energy management, since early 2014, WSD had developed a departmentwide Energy Management System based on the ISO 50001:2001 standard. In December 2014, WSD became the first HKSAR Government department to obtain ISO 50001:2011 Energy Management System certification. This certification covers the entire water supply chain, from collection, storage, transfer and treatment of raw water to the supply and distribution of fresh water and salt water.

WSD have continued to apply a host of on-going energy management programmes such as Hydropower Generation Plants, Floating Photovoltaic Systems and In-line Hydropower Harnessing Devices to help achieve its energy saving objectives and targets.